![]()

Tail Rotor Speedup Gear

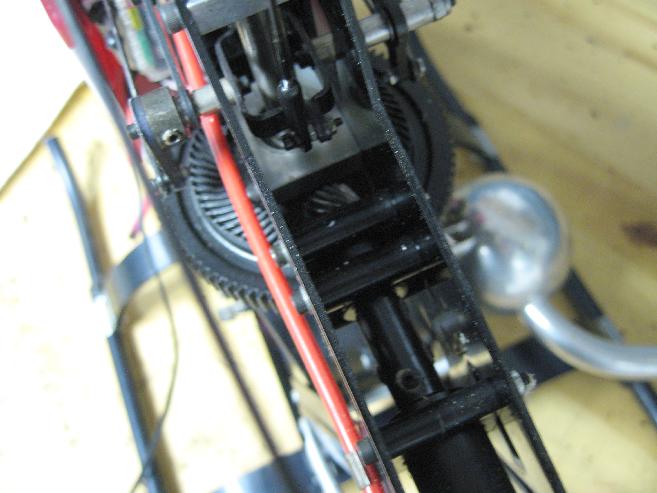

Here is the very rare and hard to find Hirobo tail speedup gear box! What is this all about?? Well, normally, the tail rotor on the Hirobo Falcon / GMP Competitor / GMP Cobra is driven by a bevel gear running off of the top of the main rotor gear:

This provides for a relatively leisurely tail rotor speed in comparison to main rotor RPM. It's really a throwback to the late 1970's with the very early Hirobo Falcon designs, and not optimal for aggressive aerobatic flight. In fact, we noticed a lack of tail rotor authority as one of our chief observations when we originally flew our modern-built Competitor using the standard bevel gear.

This shortcoming was not lost on the aerobatic contest flyers of the 1980's. We had heard rumors of an optional the "speedup gear" unit for the Competitor, but neither our 1983 nor 1988 GMP Competitor Parts Lists showed any such accessory. However, we were later sent a copy of the July, 1989 Parts List which did indeed show GMP part # 663, the "tail rtr speedup" for $75!

So, what does this mythical creature look like, and how does it work???

We were able to locate the owner of one of these very rare and hard to find units and purchase it from him. Paul from North Carolina was the original purchaser over 20 years ago after reading about it in a magazine article. He ordered one from his local hobby shop but was dismayed to find that he would have to drill mounting holes in his helicopter's side frames, so he never installed it. After putting the speedup gear away with a bunch of other GMP parts, he relocated to a new area, and the box of parts was literally forgotten for 20 years.

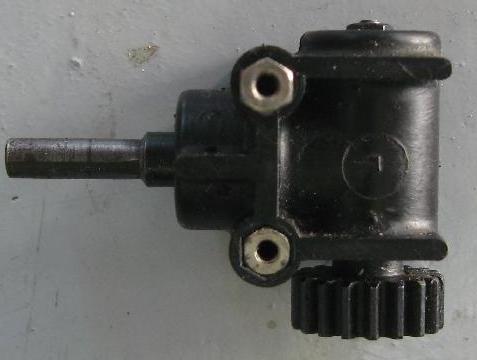

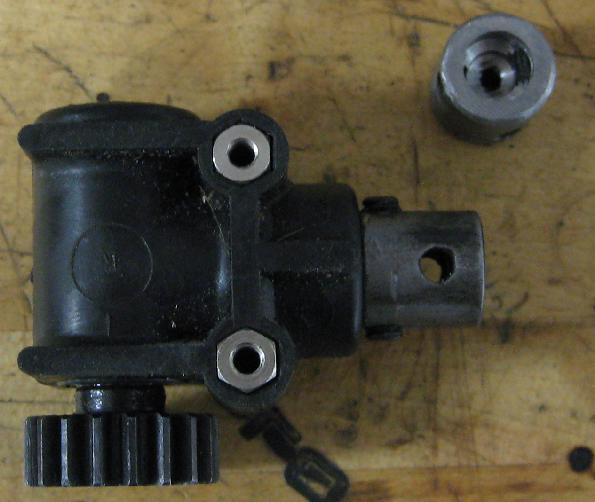

Here it is:

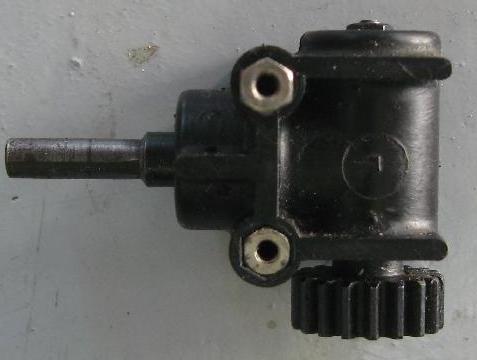

Basically, it's just a 90-degree gear drive:

The only markings on it are “L” on one side, “R” on the other, and the word "Japan" molded into one half of the plastic case. We understand that the unit was actually manufactured by Hirobo for one of the later Falcon models, most likely the Falcon 888, and was simply imported and re-sold by GMP as an optional accessory for the Competitor and Cobra (the Legend used a belt-driven tail)

So, here is how this unit drove the tail rotor off the main gear:

As you can see, the speedup unit replaces the standard bevel gear.

The only downside is that new holes likely must be drilled in the helicopter's side frames to accommodate the speedup drive. We use the word likely, because it seems some of the later competitor frames apparently came with these 2 new holes pre-drilled. This was brought to our attention by Alan Angus, who was kind enough to donate the remains of a later Competitor frame that was factory pre-drilled to accept the speedup gear. We took measurements off the factory frame to determine the proper diameter, spacing, and distance of the holes required to accept the speedup unit:

Later GMP Factory Competitor Sideframe, Pre-Drilled for the

speedup-gear. Courtesy of Alan Angus

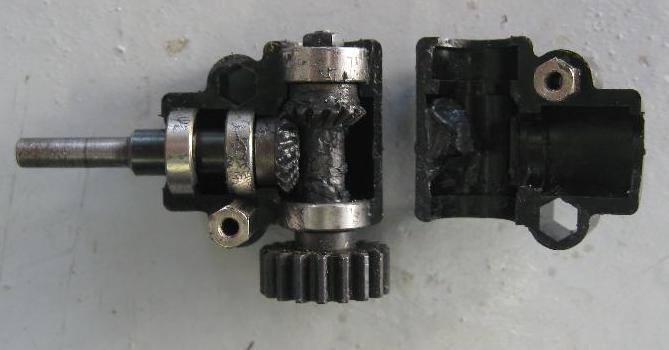

So, now it's time to install the speedup gear in our Competitor. The first order of business is cleaning the unit out, applying thread locker to the vertical gear shaft nut, lube the bearings, and apply fresh synthetic grease:

Next, we remove the standard bevel drive gear:

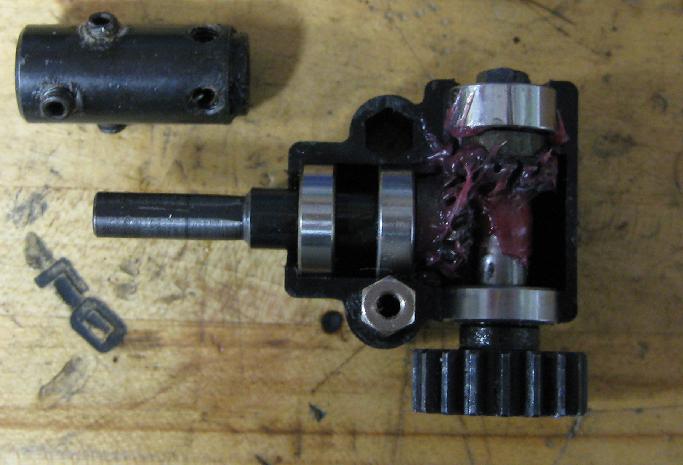

Problem! The standard black coupler that joins the tail wire to the gear shaft is much too long, plus the output shaft on the speedup unit is also too long. Together, they penetrate inside the tail boom, making installation impossible. Alan also has 2 of these speedup units in his parts collection, and theorizes that the tail drive wire went inside the output shaft and was somehow pressed or secured in place there. The idea was that a special driveshaft wire with a flattened end was keyed into the oblong shape of the inside of the speedup gear output shaft. We did see how a reliable connection between the output shaft and the drive wire could be accomplished using this idea or by flattening out a standard driveshaft wire. This speedup gear assembly is literally so rare, that nobody out there seems to know exactly how it was adopted to the drive wire. We thought and thought, and finally came up with our own way of making this unit work in our Competitor. The solution was to cut down the speedup unit's output shaft, and also cut down and machine a spare standard Hirobo tail gearbox coupler, and fit them together like so:

We figured this as the most sensible method of coupling the tail drive wire given the components and information we had access to.

Completed installation! We had to enlarge the 3.5mm mounting holes slightly rearward to alleviate a gear mesh that was a bit too tight. It should be noted that we experienced significant variations in the different black plastic main gears that we had. Some trial and error is necessary for the best gear mesh.

Next Step: Flight Testing!

A little testing on the ground to make sure the tail rotor control is working properly:

Liftoff!

A few seconds of inverted flight just to see how it feels:

Conclusion: The little tail rotor speedup gear unit is a fantastic addition to the Competitor! It makes the tail hold much better, and lends a much more modern feel to the tail control. As we had already concluded during our initial tests of the standard configuration Competitor earlier this year, the cyclic controls on this model are quite responsive, even by today's standards. Combine the tail rotor speedup unit, and you have an aerobatic model helicopter that feels almost like a modern model, save for the lower headspeed and higher overall weight of the model.

this website created in consultation with

the late John A. Gorham and the Gorham Estate

You will need the free Adobe Reader

to view and print all GMP Documents

Connect with GMP on Facebook