ARCH inc Mantis

ARCH inc Mantis

American RCH Inc Mantis (1981)

|

Specification:

|

||||||||||||||

| Documents: | |||||||||||||||

Instruction manual |

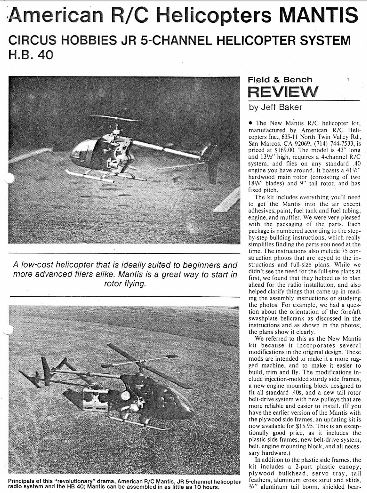

Mantis review - 1981 review of the upgraded plastic frame version. |

Super Mantis review - 1983 Field and bench review by Nick Ziroli Jr. |

|

||||||||||||

| Reports | |||||||||||||||

Introduced early 1981, a 40 size fixed pitch trainer helicopter with wooden side frames and tail drive by flat drive belt that was not particularly effective and caused a lot of tail problems/failures.

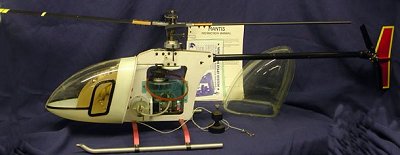

Shortly after introduction the model was update with injection moulded plastic side frames and a revised belt drive in order to take account of the initial design failings. The revised version was easily recognised as the fuel tank was also repositioned to behind the motor such that as the tank emptied the balance moved forward slightly; this being a safer option than the alternative of ending up with an empty fuel tank and CG behind the mast.

American RCH Inc Super Mantis (1981)

Introduced in late 1981 around the same time as the fixed pitch version received its upgrades; collective pitch for 46-50 size engines with the same head as the flybar equipped Commander.

Super Mantis advert late 1983 though more about the Blue Thunder model than the Mantis itself. |

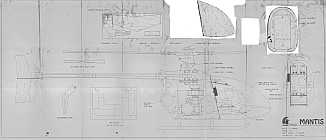

1984 Mantis / Super Mantis general details. |

Below are comments I have received from one modeller but they generally reflect the experiences with the Mantis. The starting method described was used a lot in the late 70's and early 80's and I remember going through a few Schlüter cooling shrouds on my Heli-Baby by using the same method; it was years before I saw the use of a belt and upgraded to that method. As an historic note, many of the helicopters supplied for learner received a mixed reputation so the Mantis is not unique and the reason I have picked this review is that at the end he does admit that part of the problem was inexperience on his part and personally I would have to agree based on my own problems when learning without assistance.

To this end, I have an part started early kit and intend to build it with the experience of hindsight however, I do not intend to actually modifying it. From this I hope to be able to prove, or otherwise how well it will actually fly in that configuration.

First of all, I really enjoy your site, and have only looked at about 1/4 of it. I was stopped in my tracks when I saw the pictures of the American Mantis. That was my very first helicopter, which I purchased in 1981. It really was an awful kit. I was fortunate enough to have gotten the plastic framed version instead of wood, but that's where the good ended. The kit used self tapping screws on each side of the heli to attach the frames to the bearing blocks. These would strip out easily, so I got smart, and drilled holes all the way through the blocks, and used a long bolt to hold things together.

Another weak point was the tail rotor drive pulley on the main shaft. This brittle plastic pulley was held on the main shaft by a single set screw that threaded directly into the plastic. The idea was that the screw would "grip" the main shaft, but there was no flat or indentation for the screw to grip - just the round smooth shaft. Any pitch put into the tail rotor created drag, which in turn caused the pulley to slip. Tightening down the set screw caused it to strip out in the plastic pulley. It was truly a love/hate experience. Every time the heli would get light on its skids, I would attempt to hold the yaw steady using tail rotor, but it would begin to spin uncontrollably because of the slipping pulley.

Another joke was how they expected you to start the engine. They provided a length of hard rubber with a round cross section. It wasn't a belt loop, but just a length of this material. The idea was to hold the heli still with your foot on the skid, then manually pull the "belt" against the pulley on the fan hub, spinning the engine. If you got any fuel on it, it was useless as it couldn't grip the aluminium pulley at all. Surprisingly, I was able to start the engine a couple times this way, but only after a lot of attempts, and sore fingers. Eventually, I installed a vacuum cleaner belt over then engine, and used an electric starter.

I never did fly it successfully, in part to my having no previous experience with helicopters, but largely to the poor materials and design. For some reason, this didn't end my love with helis, and I went on to a "hi-tech" Schlüter Mini-boy, which was built like a tank in comparison to the Mantis.

I wish you luck, and truly hope you can get the Mantis controllably airborne. Please provide pictures if you get it going.