Hirobo Gazelle (1976)

|

Specification:

|

||||||||||||||||||

| Documents: | |||||||||||||||||||

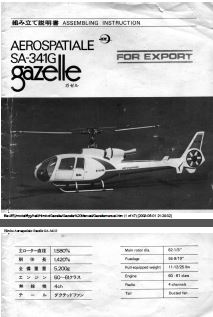

Gazelle SA341 assembly and flying instructions |

|

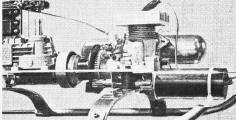

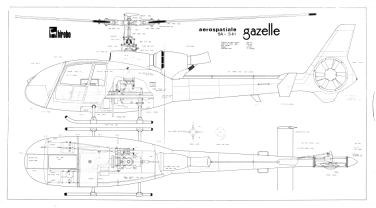

Gazelle build manual - Flatbed mechanics. |

|

||||||||||||||||

| Reports | |||||||||||||||||||

Hirobo's first RC helicopter and followed the trend at the time in that helicopters had to be a 'scale' subject. Developed for '60' size engines with flatbed mechanics, Hirobo's original head and additionally incorporated what was a bold and unique move, a fully functional Fenestrom fan; unlike the Schlüter Gazelle of a few years earlier which used a 'standard' two blade tail rotor. The flat bed mechanics achieved collective pitch operation by raising the whole swashplate and linkage assembly with a pivoting arm. Whilst simple in execution it did have a drawback in that as the collective arm rotated to move the linkages up or down from the central position, it also moved them forward; because the servo's and their rod length's were fixed this was in effect the same action as putting in slight 'back' and right stick movements at the same time. Thus changes in collective pitch resulted in unwanted cyclic pitch interaction and due to the design of the rotor head also resulted in a 'pitch' change to the flybar paddles. This head was very stable but the movement of the flybar paddles made it very inefficient outside of a small range of setting around the Zero flybar paddle position. Pilots generally set this position to suit their flying style; for beginners it would have been at the 'hover' position so as to give good control whilst learning; for more advanced pilots it was changed to give zero paddle setting at the 'circuit' position so as to give good flight performance.

The control system was four channel, requiring only four servo's as one servo did the duty for collective and throttle control plus cross connected by a linkage to the tail rotor servo arm also provided coupling to achieve mechanical collective-tail rotor pitch mixing. An additional feature was the inclusion of a 'pull start' system thereby removing the need for heavy starting equipment i.e. Battery and external starter motor.

Gearbox and original head detail |

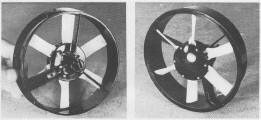

Fan close up |

General parts list - 1977 listing including the Gazelle.

In order to remove the 'unwanted' effect of the paddles moving with collective pitch, the Collective de-coupler rotor head was fitted and was also available as a conversion kit for retro-fitting to a original rotor head.

For 1979 as per the 60 size Huey, the Gazelle was fitted with the new scale rotor head, revised collective 'pitch up' linkages which removed the collective-cyclic mixing of the original design, option of hand pull or belt start systems and optional 'free-wheel' adaptor to allow autorotation.

For the ultimate though adding an extra 0.5 Kg or so in weight, the pull start could be replaced with an onboard electric starter; cost £120 which was the equivalent to the cost of an engine and gyro together so did not really sell to the 'average' helicopter modeller.

Gazelle (1976) with Fenestron transmission inside the boom and separate tail.

HIROBO GAZELLE WARNING

Here is what can go wrong due to ageing of the plastic blades; these blades were taken from my Gazelle after it 'threw' a tail blade whilst test running the engine. Luckily the engine was not running properly having been stood for a few years so it was on the test bench without its main blades; I hate to think what would have happened if it had been in flight !!!!!!!!!!! As you can see they have 'hardened' with age and another of the blades was obviously just about to fully let go and the others have cracks starting on both sides of the main spindles.