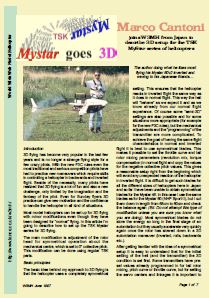

TSK Mystar

TSK helicopters were at the high end of the market being fully metal construction when a lot of manufacturers were moving towards plastics. The Mystar range whilst still keeping the principle of metal construction were designed to be of more simplified construction thereby bring them into the price range of the average modeller who wanted a good machine that did not need the expense of extra 'Bling'.

TSK Mystar 30

|

Specification:

|

||||||||||||||||

| Documents: | |||||||||||||||||

Mystar 30 manual - Build manual with parts listing. |

decal |

Mystar 3D setup - Article covering mod. to make the Mystar 3D capable. |

decals |

||||||||||||||

Mystar 30 (Original Body)

Mystar 30 (Original Body)

Though '30' size for 550mm main blades, it was a very high spec helicopter with metal rotor head, 10mm main shaft, metal washout unit and swashplate, aluminium or carbon frames, push-pull mechanics with 2.3mm pushrods and fittings, fully ball raced, belt driven tail, hex top start and fibreglass canopy. However, the 30 was quite a complex build and the instructions had to be followed precisely otherwise the helicopter might have to be dismantled to get that 'forgotten' bit back in; especially the tail rotor servo. The main gear was moulded from plastic however, Delrin gears were available as an upgrade. The head also incorporated control arms for the main blades and Bell-Hiller mixes that had multiple mounting holes thus allowing a large degree of 'mixing' to be undertaken. The helicopter could therefore be configured as a 'tame' learner machine, full 3D capable or variations in-between the two.

Note that the main shaft can be replaced with a Raptor 30 spare as it would appear to be identical and slots straight in....

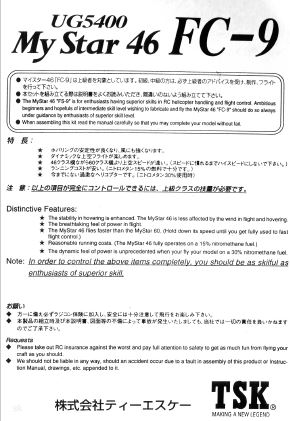

TSK Mystar 46

|

Specification:

|

||||||||||||||||

| Documents: | |||||||||||||||||

Mystar 46 Exploded views. |

|||||||||||||||||

Mystar 46 build manual |

Mystar 3D setup - Article covering modifications to make the Mystar 3D capable. |

|

|||||||||||||||

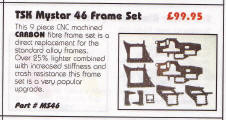

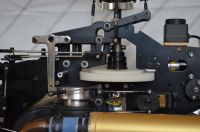

Third model in the Mystar range and whilst the 46 looked very much like a 30,TSK actually based the design on the Mystar 60. Compared to the 30 the entire frameset of the 46 was of 'stepped' design to accommodate the wider engine and also extended back farther behind the main shaft to provide the extra length. Though using the same boom as the 30, the 46 was fitted with twin supports. The tail rotor servo location on the 46 has also been moved, to eliminate one very annoying idiosyncrasy of the Mystar 30; if you don't install the tail rotor servo before joining the upper frame pieces, you have to basically disassemble the servo (or helicopter) to get it in. The 46 blade grips use 4mm bolts (3mm on the 30), but otherwise the heads were identical except that blade length was 600mm for the 46. It had the same tail rotor pinion assembly, tail box and tail rotor but had slightly larger blades. The 46 also came with machined Delrin main gears as standard; this upgrade was an option for the 30 that was supplied with moulded black plastic gears as standard. Push-Pull linkages on collective and cyclic controls with 10mm diameter main shaft and is the same mast as fitted to the Mystar 60.

A couple of faults emerged on the 46, the first being the tendency for the upper frame pieces to crack both sides just in front of the lower shaft main bearing housing; a useful upgrade was to fit Carbon Fibre replacement frame sides as these did not suffer cracking. Alternatively the frame could have a 'doubler' fitted in this area and secured with longer bolts to the bearing housing and front mounting hole; additionally glued in place with epoxy. The second was wear in the starter clutch one way bearing and this was because being the same size as fitted to the 30 (10mm OD), it could not cope with the extra torque required to start the larger engine. Not a serious fault but annoying and expensive plus it always happened at the start of a flying session, never at the end....... Mind you I have it on good authority that shuttle one way bearings will fit however, to remove the bearing you have to drill out the bottom of the clutch in order to be able to 'drive' it out before 'driving' in the replacement.

Mystar 46 NB

TSK Mystar 60

|

Specification:

|

|||||||||||||||||||||||

| Documents: | ||||||||||||||||||||||||

Mystar 60 build manual Construction manual with exploded parts views. |

Mystar 60V2 build manual |

Mystar 3D setup - Article covering modifications to make the Mystar 3D capable. |

decal |

|||||||||||||||||||||

Mystar 60 (original body)

Mystar 60 (original body)  Mystar 60 NB (new body)

Mystar 60 NB (new body)

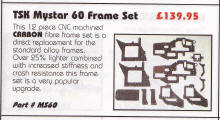

Second in the Mystar range and designed as a general purpose large model capable of all the flight manoeuvres then currently thought possible.

Came with the option of carbon or metal frames and a larger starter bearing (14mm OD) to take the extra torque of starting a 60. Boom length of the early model was 790mm and used the Brown tail drive belt (504-5200) for reference the belt was coded 686XL. Later models used 810mm tail booms and black belt (504-5201) with longer 720mm main blades. option extra allowed for a driven tail rotor during autorotation. Incorporated push-pull ball raced linkages for collective and cyclic controls and metal swashplate with ball bearing anti-rotation linkages.

Mystar 60 NB

TSK Mystar 60 V2

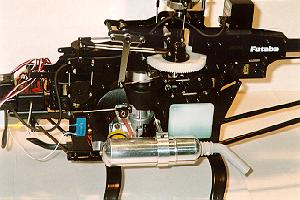

Mystar 60 with 4-stroke engine

TSK Mystar 60V2 EMS (2000)

ECCPM version of the Mystar 60V2 for more direct control of the rotor head, made possible with the better spec of servo's then being made available. Originally released in 1999 as an upgrade kit for the original Mystar 60 then followed by the full kit version based on the V2 in 2000.

The EMS conversion kit consisted of the following:

- Upper main frames;

- A metal 120 degree three point swashplate;

- A set of metal A-arm;

- Metal push-pull bell cranks for swashplate controls; and

- Pushrod, cross members and other accessories.

Length 1410mm, Main rotor Diameter 1500mm, Tail rotor Diameter 270mm, gear ratios 9.7 : 1 : 5.1, weight 4300 Gram nominal.

The EMS frames houses three servos on the left side, and one servo on the right. Controls to the swashplate was through a 3 servo 120 degree ECCPM arrangement, with the left front servo controls the 10 o'clock point, the right servo controls the 2 o'clock point, and the left rear servo controls the 6 o'clock point of the swashplate. All swashplate controls were through push-pull bellcranks, with the 6 o'clock point control by an A arm that goes between the upper main frames; the rudder servo remained in its original position on the left. The instructions supplied with the conversion kit was apparently extremely well written and quite straight forward however, radio set-up was not covered and needed researching from other material in order for the inexperienced to set the model up correctly.

TSK Mystar GS60

|

Specification:

|

||||||||||||||||||||||

| Documents: | |||||||||||||||||||||||

Mystar GS build manual |

decal |

||||||||||||||||||||||

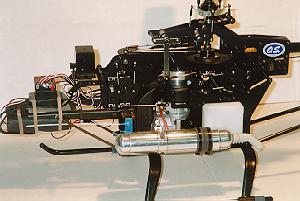

Based on the Mystar 60 with the same all metal and ball raced build with the same options of Metal or Carbon frames, Belt or Shaft driven tail. Engine is a modified 24cc petrol engine in a similar fashion to the 32cc Black Star unit. Review below by unknown American author;

Gasoline powered helicopters are quickly finding there place with R/C Helicopter Pilots. TSK’s new machine meets the needs and demands of this new market with the release of their new machine the Mystar Gas. This machine is slightly larger in size to the Mystar 60, and shares many common attributes.

There are many advantages to Gas powered helicopters. First of all, it is much more economical on fuel. A gallon of the best gasoline money can buy might cost no more than $2, while a gallon of nitro based fuel can cost as much as $25 a gallon for good fuel. The gas engines do consume more fuel, however even if they used twice as much fuel, gas is cheaper. In some countries, 15% nitromethane fuel costs as mush as $70 per gallon.

Gas powered engines are generally easier to start and tune. The spark plug ignition is easier than using glow plug drivers, and spark plugs generally have a longer life then glow plugs. The carburettors provide more consistent fuel air mixture, and require much less adjustment due to weather changes. Almost all gas engines used in helicopters have pull starts on them which makes starting at the field much easier. Very little field equipment is required. You just need a way to put fuel in the tank.

The engine in the Mystar Gas is a modified 24cc gas engine. This engine was modified by the same company as their 32cc gas engine found in the Blackstar DL Gas machine. The engine comes complete with an exhaust system and pull starter. Preparation and dial indicating the engine shaft is not difficult. The centre hub is already bolted and centred on the engine shaft so that dial indicating the centre hub is not necessary. I do recommend checking this anyway to be sure that everything is perfectly centred and straight. I had to make some adjustments to mine to make it perfectly straight. The hub is mounted on two stems on the engine’s fan. I used a small file to take a little off of the high side, and everything went on centred from there. Everything on the centre hub, clutch system, and top start should be dial indicated. This type of starting system is very rigid, however can cause vibration problems if not assembled straight.

The clutch system is very similar to the one found on the TSK Blackstar series. Each clutch shoe is made from plates of steel stacked together to make a solid block. A brass sleeve is inserted for the pivot, and replaceable springs hold the clutch shoes together. This clutch design is the one of the most indestructible design available. The only parts that will break under normal conditions are the clutch springs, which cost less then $5. The clutch bell is also very durable. It is machined out of aluminium, and has steel pinion gear. The clutch bell is supported by two bearings. One is inside the clutch bell, and rides on the engine shaft, and the other supports the bell from the upper bearing block. This prevents the bell from any misalignment. Shims are also provided to be sure that there is no slop in the clutch system. Engine alignment and gear mesh is important, and the easiest way I found to do this was to leave all of the screws loose until the most of the frame construction was done. I then tightened the engine mount and bearing block mount screws at the same time. The gear mesh and alignment was almost perfect. A minor adjustment on the gear mesh was necessary, however was very easy because the bearing block holes are slotted to adjust this.

The starting system is the same as the original 60 size system found on the Blackstar helicopter. This consists of a one-way bearing coupler mounted to the top of the engine shaft. This coupler is then engaged by a starting shaft from the top of the helicopter.

The Mystar Gas helicopter uses 720mm Main Blades. I have chosen the New Hi Products GS-25 main rotor blades. These are fibreglass blades with a semi-symmetrical S-camber airfoil. These blades are very high quality, and require very little preparation. They were designed specifically for this helicopter which makes them a perfect choice for blades.

The Mystar Gas shares quite a few common parts to the Mystar 60. The gas machine uses the same high performance rotor head found on the Mystar 60. This head is completely machine from aluminium, and comes factory pre assembled. The swash plate is like the one found on the new Mystar 46, and is also completely machined from aluminium. This swash plate is an upgrade from the original Mystar series swash plate, and I suspect that it will be used on all future kit developments.

The upper drive components such as the autorotation hub, main shaft, and belt shaft are compatible. The belt pulleys and belt have been upgraded to the new design which is also available for the original Mystar 60. The pulleys are made from aluminium, and the belt has more defined teeth. This new belt does not were out the pulley, and has less friction then the original belt system found on the Mystar 60. The belt is very direct. There are only two drive pulleys, one in the front, and one in the back. This is accomplished by running the belt off of the main gear at the correct gear ratio instead of slowing it down in the rear. There is no slop in the tail drive system which might be found in a wire or torque tube drive. While the torque tube drives may be more efficient then belts, there is very little loss of power, and the belt is much easier to maintain. Belts also hold up better in a crash, while tube drives usually have to be replaced.

Many of the frame parts are compatible with the Mystar 60. These include the servo frame, upper frame, and electronics mounts. The lower frames however, have been completely redesigned. They are made from 2.5mm carbon fibre. The design is extremely strong, and the engine is supported from both the top and bottom. The fuel tank mounts in the front, just under the servo frame. Some small changes were made to the collective system to accommodate the lower frames. First, the servo was mounted on the opposite side of the helicopter to allow the throttle servo to be mounted in the rear. The collective arm was changed to allow clearance for an added cross member which gives additional support to the lower frames.

Flight performance is almost exactly what you would expect from the stereo types on gas engines. The machine is heavier then the original Mystar 60. It weighs in at 12 pounds dry without blades. With this additional weight, the machine is more stable and smoother in forward flight. It has plenty of power and top speed, however slight less acceleration. It definitely takes a short while to get used to the sound and RPM ranges suitable for a gas helicopters. The gas engine does not bog down like most 60 size engines do when you give them too much or too little pitch. This actually makes pitch and throttle curves less critical, however to get the power you really must fine tune your pitch and throttle curves. The overall rotor head RPM can be lower then a typical 60 size machine. This is because the engine has more torque and power at a lower RPM range then a 60 size engine. Gas powered helicopters will be proving themselves over the next few years, and the Mystar Gas will definitely be in the ranks with the best of them.

TSK Mystar Parts - A cross reference list for 30-46-60/V2/GS

TSK Mystar GS62

This is one big helicopter as can be seen by comparison with a Mystar 46.

Designed for camera mounting or light duty aero-spraying.