PHI Hurricane

| |

Specification:

|

||||||||||||||||||

| Documents: | |||||||||||||||||||

| |

|||||||||||||||||||

PHI Hurricane (199#)

Update for Oct 2002 saw the basic Hurricane fitted with a rotor head button for easier hand slowing down with list price of $600.

The basic version of the Hurricane was discontinued in 1993.

Specifications

- Carbon boom braces with CNC machined aluminium boom brace ends

- Super tough nylon landing gear struts with aluminium skids

- 52 high quality bearings total

- Aircraft grade aluminium and 12L14 steel +/- 0.001in. tolerance on all machine work

- Main blades, engine/muffler and radio equipment not included in kit

- Finishing caps and header tank shown in pictures not included

- Self aligning steel centrifugal clutch/CNC machined aluminium clutch bell with heavy duty clutch liner

- Dual ball bearing supported clutch bell and start shaft

- CNC custom machined fan hub

- CNC machined aluminium rotor head - floating axle design

- Triple bearing blade grips with oversize thrust bearings

- CNC machined aluminium see saw and mixing arms

- Long 4mm Flybar with lightweight paddles

- CNC machined aluminium washout and mixing arms

- CNC machined aluminium swash plate

- Anti-rotation unit and start cone come standard

- G10 stacked main frame set with CNC machined aluminium spacers

- CNC machined aluminium main shaft bearing blocks including main shaft thrust bearing

- Forward fuel tank/rear-facing engine cylinder for easy glow plug access

- CNC machined Delrin main gear with lightening holes (93 tooth standard, 86 tooth optional)

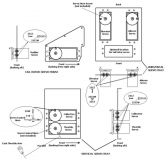

- Aluminium horizontal and vertical servo trays, gyro tray, and radio equipment floor

- Optional front mount location for tail rotor servo (scale fuselage application)

- All machined aluminium bellcranks fully ball raced

- Triple bearing CNC machined aluminium autorotation hub

- Rear G10 tail rotor servo mount/direct no-slop linkage

- Kevlar-reinforced belt drive tail rotor

- Steel tail rotor front transmission gear with dual ball bearing supported shaft

- CNC machined aluminium tail rotor gear box and pulley

- Dual bearing tail rotor washout assembly

- CNC machined steel tail rotor hub

- Triple bearing tail blade grips with thrust bearing

The YS range of engines could also be fitted which required a separate adaptor and some modification to the fan as the engine sat higher than other makes.

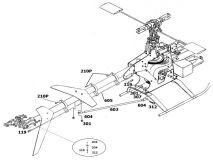

Hurricane 3D Pro replacement parts list - Hardware list

PHI Hurricane 3D Pro build and flying article by James Wang from January 2001 MHW.

Parts and construction drawings.

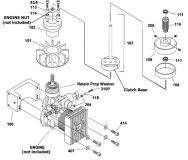

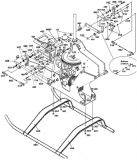

| Chapter 1 | Engine Fan and Clutch Assembly | |

| Chapter 2 | Rotor Head and See Saw Assembly | |

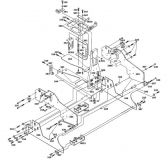

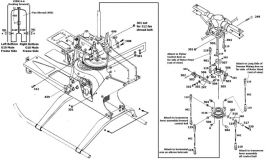

| Chapter 3 | Main Frame Assembly - View A | |

| Chapter 3 | Main Frame Assembly - View B | |

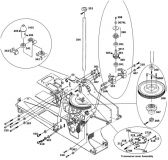

| Chapter 4 | Control System Assembly | |

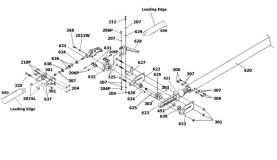

| Chapter 5 | Fan Shroud, Swashplate, and Washout Assembly/Rotor Head Installation | |

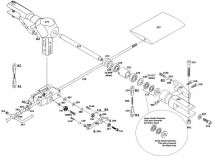

| Chapter 6 | Tail Rotor Assembly | |

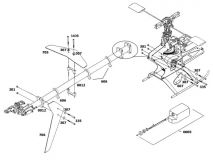

| Chapter 7 | Tail Boom Assembly - View A | |

| Chapter 7 | Tail Boom Assembly - View B | |

| Chapter 8 | Radio Installation/Canopy Assembly |